SICAPERMA is uniting regions and innovation to build Europe’s first recycled permanent magnet value chain.

Nd-Fe-B magnets are the strongest, representing a strategic cornerstone of Europe’s green and digital transition.

They sit at the heart of wind turbines, EV motors, electronics which are key enablers for entire sectors and fundamental pieces for the green and digital transitions.

Europe still relies heavily on external supply, while demand is rising fast, which makes secure and circular supply a European priority.

SICAPERMA’s innovative approach transforms end-of-life products into market-ready magnets, offering a potential solution to this problem. By establishing a connected, interregional value chain, Europe can reduce its dependency and boost its resilience.

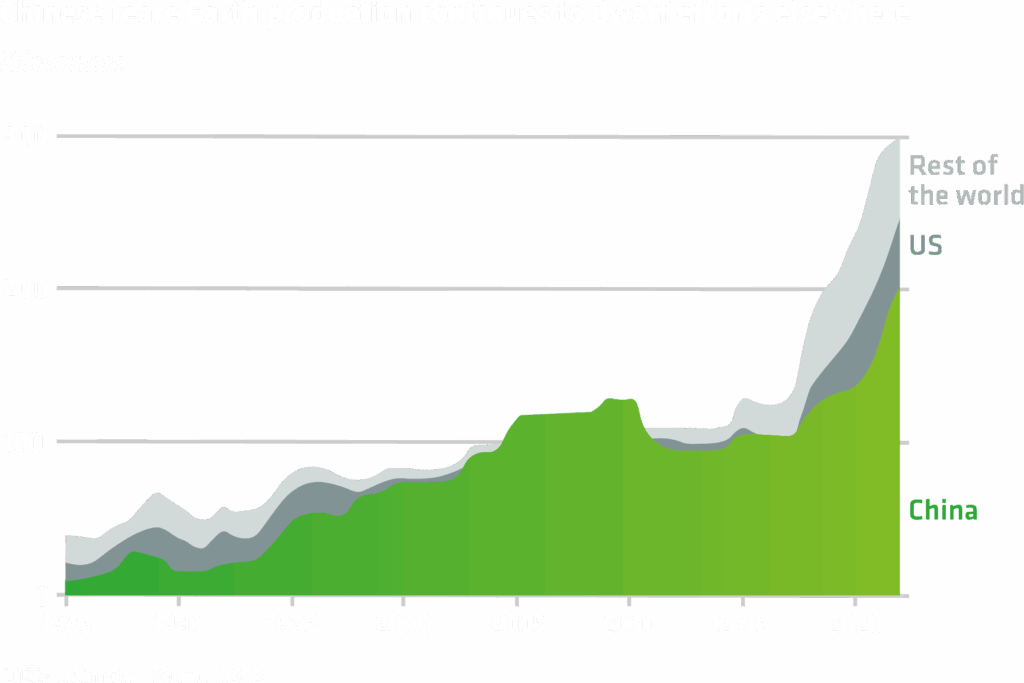

With China currently controlling 98% of the supply, a single export stoppage could paralyse Europe’s strategic goals — an urgent risk in today’s uncertain geopolitical climate.

SICAPERMA’s innovative approach transforms end-of-life products into market-ready magnets, offering a potential solution to this problem. By establishing a connected, interregional value chain, Europe can reduce its dependency and boost its resilience.

With China currently controlling 98% of the supply, a single export stoppage could paralyse Europe’s strategic goals — an urgent risk in today’s uncertain geopolitical climate.

Almost all of the rare earths used in Europe's permanent magnets are imported, with around 98% coming from a single source: China.

In 2022, only around 1% was recycled, and to this day, Europe still lacks an integrated Nd-Fe-B value chain.

As demand surges, scaling up recycling is the only way to close the gap, strengthen resilience, and reach profitability.

An investment-ready value chain for recycled Nd-Fe-B magnets

Multi-stream PM extraction from end-of-life electronics and appliances.

Producing industrial-scale recycled sintered and polymer-bonded magnets.

Fit recycled magnets into sensors and motors.

11 regions are joining forces to prove the loop and promote interregional collaboration and investment. Our partnership covers every stage of the process — from supply to demand, while combining the right technologies to drive innovations forward.

SICAPERMA will

Increase the technological maturity of the solutions

Reduce economic risks for investors

Equalise or lower the costs of recycled permanent magnets to the main Asian benchmarks

Demonstrate the return on investment (ROI) across the entire value chain.

The Interregional Innovation Investments (I3) Instrument supports interregional projects as they scale up and reach commercialisation.

Subscribe to the SICAPERMA newsletter to stay up to date with the latest news, breakthroughs and results.

It is the First Tech Area critical to leading EU value chains where Less Developed and Transition Regions can become Leaders. SICAPERMA will build a tech-based value chain that does currently not exist in Europe and will do so by tapping into less developed regions’ uncovered tech capabilities. These will be connected for the first time into a full interregional EU demonstration ecosystem that will commercialize and deploy innovative recycled PM and underlying tech at high-end material market volume by M30.

Today, China provides for 98% of EU demand in REE magnets4 and even provides 100% of EU supply of heavy REE while Turkey provides 99% of our Boron.

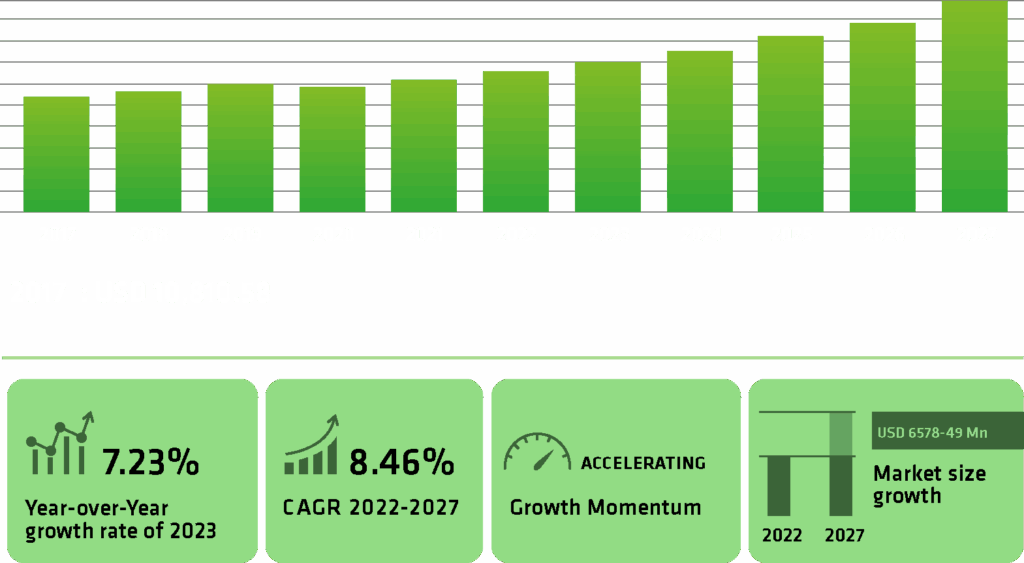

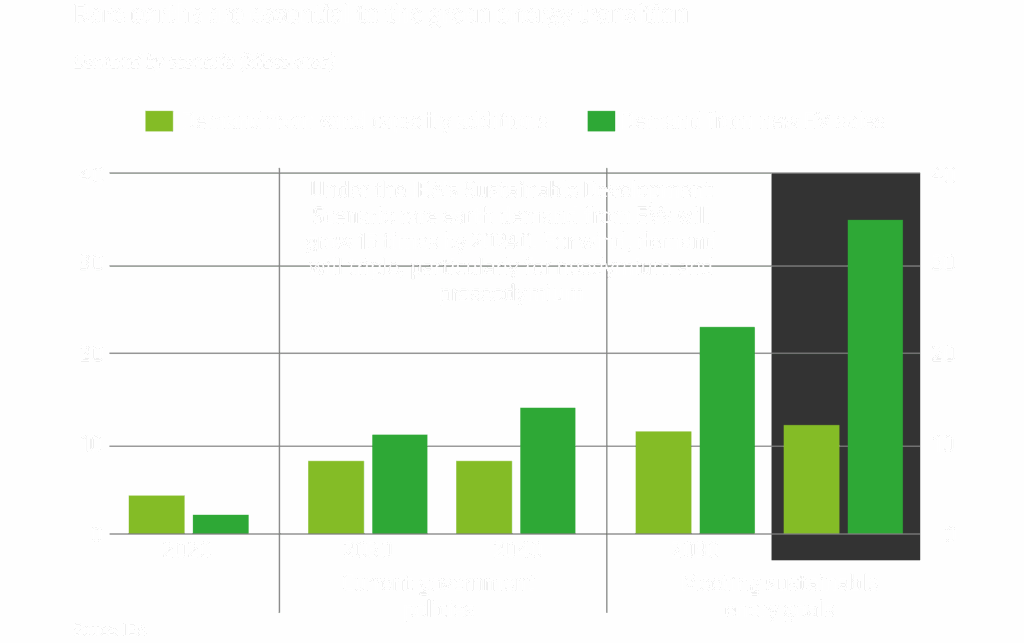

In 2022, only one percent of rare earth metals were recycled, despite demand being set to rise sharply. In the EU, recycling rare earth metals is not yet economically viable because dismantling products to extract them is too expensive (CEPS, 2022). The challenge lies in the fact that rare earths appear in very small amounts, embedded in complex products where components are glued together, making recovery even harder. Given that 70,000 tonnes of rare earths from wind turbines are expected to become recyclable permanent magnets, the European Commission has set a target of 1.5 million tonnes of recycled rare earths by 2033. However, although collection is improving, permanent magnets are still being repurposed in Asia. Europe is hindered by high entry costs and technologies that are competitive but not fully integrated into the value chain.

Permanent Magnets (PM) gained unprecedented visibility within the past 5 years in conjunction with several trends – when the booming electrification meets COVID, Microchip and Ukrainian crises. PM consist of hard materials that produce a persistent and constant magnetic field (force that can move other ferromagnetic materials). The best performing PM ar made of Rare Earth Elements (REE) and are strategic as they are essential to a wide rage of applications – from electronics (mobile phones, cameras, or computer drives) to wind turbines or Electric Vehicles (EV). REE comprise the so called “light” REE Nd (Neodymium), Pr (Praseodymium), Sm (Samarium), as well as minor “heavy” REE such as Tb (Terbium) as well as Dy (Dysprosium). REE PM are a critical input to over 200 different commercial product groups1 and PM themselves are the primary user group for rare earth metal elements.

Vasileios Rizos, Edoardo Righetti, Amin Kassab (2022). CEPS In-Deph Analysis: Developing A Supply Chain For Recycled Rare Earth Perfmanent Magnets In The Eu. Challenges and opportunities. INSPIRE December, 2022 – 07’

Source: ceps.eu

After registering, we will keep you informed on the progress of the project and send you the investor pack upon completion.